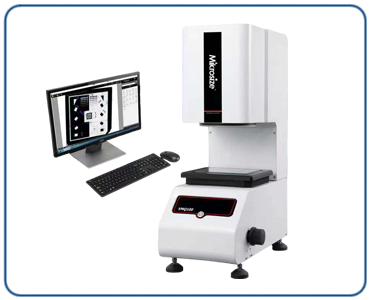

VMQ-100 instant video measuring system

• Measuring sample can be placed randomly without fixture positioning; software can identify and match automatically.

• Unlimited dimension measurement; measurement task can be completed within 1 second.

• CAD drawing import for direct measurement.

• One-time measurement of the same type of measuring sample.

• Unique patent technology of edge extraction and lens distortion correction.

• Automatic lighting, greatly improves the repeatability.

• It can be compared with the measurement accuracy and repeatability of traditional video measuring machines.

APPLICATIONS

This system is widely used in machinery, electronics, mold, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, terminals, mobile phones, household appliances, printed circuit boards, medical devices, watches, knives and other fields.

Easy to operate without training

• Anyone can get started quickly without training.

• Simple interface, intelligent measurement, optimized operation process, real-time operation tips.

• All measurement data can be automatically recorded, statistical analysis can be generated with one key, measurement results can be printed in various file formats or directly printed by printer.

Various function, automatic report

• The software is divided into three functional modes: measurement setting, continuous measurement and statistical analysis.

• Continuous measurement can be used for real-time measurement and it can judge NG / OK without pressing the key, providing 80 tools of extraction and analysis , including feature extraction tools (such as maximum point, center line, arc, peak circle, etc.), auxiliary tools (such as arbitrary point line circle, fitting line, fitting circle, tangent line, inscribed circle, etc.), intelligent annotation tool, geometric tolerance tool, special application tool (such as R angle, etc.).

Technical features

| Dimensions | 480 x 240 x 680 mm | |

| Weight | 30 kg | |

| Working stage capacity | 3 kg | |

| Software | Fom2d | |

| Camera | 5 MegaPixel CCD industrial camera | |

| Lens | Double telecentric lens | |

| Illumination | Program controlled parallel light or telecentric parallel light, each section of brightness is controlled independently | |

| Field of view | 30 mm ~ 100 mm | |

| Focus | Manual | |

| Measuring accuracy | ± 3 µm | |

| Measuring function | Point, line, circle, multipoint line, multipoint circle, automatic circle, arc, multisection circle, automatic R angle, contour scanning, fixed point, peak line, circle, etc. | |

| Tagging function | Aligned, vertical, angular, radius / diameter | |

| Geometrical tolerance | Straightness, roundness, symmetry, profile, etc. | |

| Virtual structure | Center line, bisector, tangent point, tangent point of circle line, circle center, line center, etc. | |

| Automatic template matching | Support | |

| Report function | SPC analysis report (CPK, CA, PPK, CP, PP) | |

| Software customization | CAD import profile analysis, automatic management link, APP management application | |

| Measuring quantity | 99 pieces/second | |

| Template quantity | Unlimited | |

| Power source | AC 100 ~ 240 V, 50/60 Hz | |

| Working environment | Temperature: 23°C ± 2°C; Humidity: 20 – 80% RH | |

Packing list

| Machine mainframe | Dell 24” computer | Mikrosize measuring software |

| Telecentric lens | High resolution camera | Surface lighting |

| Calibration block | Power line | Product certificate |