N4 portable hardness testers

Portable hardness tester, 147 − 1840 N (15 − 187.5 kgf)

Capacity: 0 − 20 / 145 / 235 / 335 mm

Rockwell EN ISO 6508, ASTM E−18

Plastic testing EN ISO 2039

HBT and HVT methods

The N4 portable hardness tester possesses a clamping device consisting of clamp in light-alloy with quickly adjustable threaded spindle and clamping toggle. According to customer’s request, test unit N1A 001 with spring sleeve or one of the load adjustable test units can be selected.

Operation:

The part to be tested is clamped between the anvil and the test head, after which the load is applied to the indentor. Subsequently the reading is taken from the dial gauge.

Load-adjustable test unit:

N1P 000 − for plastic testing in compliance with EN ISO 2039−1 − 5, 13,5, 36,5, 98 kgf

N1R 000 − for Rockwell test in compliance with EN ISO 6508 − 60, 100, 150 kgf

N1S 000 − for Super Rockwell test in compliance with EN ISO 6508 − 15, 30, 45 kgf

Test methods:

All Rockwell methods in compliance with EN ISO 6508, ASTM E−18. HBT non-standard in depth methods are possible in load range 294 − 1840 N (30 − 187.5 kg).

ROCKWELL (compliant with ISO 6508, ASTM E18)

| HRA | HRBW | HRC | HRD | HREW | HRFW | HRGW | HRHW | HRKW | HRLW |

| HRMW | HRPW | HRRW | HRSW | HRVW | HR15N | HR30N | HR45N | HR15TW | HR30TW |

| HR45TW | HR15WW | HR30WW | HR45WW | HR15XW | HR30XW | HR45XW | HR15YW | HR30YW | HR45YW |

N6 portable hardness tester

The N6 portable hardness tester consists of test unit N1E 000 (complete with dial gauge, dial gauge cover and spring sleeve) with load lever and Intest sensor with tensioning nut, clamping clip and spring link, including test sample. The standard design consists of load level 62.5, HRC hardness value indicator, device case, hardness comparison table and instruction manual.

Operation:

The testing machine is positioned in the bore and fixed by clamping action. The test load is applied via hand lever. Subsequently the reading is taken from the dial gauge in HRC values.

Application:

For bore diameters from 36 to 110 mm.

Insertion depth up to 400 mm.

ROCKWELL (compliant with ISO 6508, ASTM E18)

| HR 62.5 |

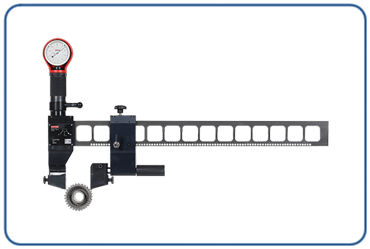

N7 portable hardness testers

The N7 portable hardness tester consists of test unit N1E 000 (complete with dial gauge, dial gauge cover and spring sleeve) with load lever, the measurement head with built-in spring link, including hardness testing diamond and the clamping device. The standard design consists of a load level 62.5, HRC hardness value indicator, tool kit, hardness comparison table, device case and instruction manual.

Operation:

The testing machine is positioned on the work piece and clamped to the requested test point. The test load is applied via hand lever. Subsequently the reading is taken from the dial gauge.

Application of N7F:

External teeth module 2 − 10

Maximum tooth measurement width 140 mm

Application of N7P:

External teeth module 3 − 35

Maximum tooth measurement width 700 mm

ROCKWELL (compliant with ISO 6508, ASTM E18)

| HR 62.5 |