Magnetic testing

Magnetometer

Magnetometer MF-1M is designed to control the residual magnetization and study the magnetic heterogeneity of the surface of ferromagnetic products, to control the level of residual magnetization before welding gas and oil pipes, to control the induction of static (DC), alternating (AC) and pulsed magnetic fields generated by various magnetic and electromagnetic devices, such as magnetic particle flaw detectors, magnetic tables and chucks of grinding machines, demagnetizing devices, permanent magnets etc. The device has the ability to create a measurement archive that can be transferred to a PC using special software.

Features:

• Simplicity and convenience of measurements

• Friendly menu

• Static (DC), alternating (AC) and pulsed magnetic fields

• Several units of measure

• Wide range of measurement

• Different types of probes

• Robust and shockproof housing.

Standard supply:

• Electronic unit

• Probe

• Batteries AA – 2 pcs

• Charger

• USB cable

• Case

• Operating manual

Optional accessories:

• Probes (axial and/or transverse type)

• Charger

• Magnetic test samples

Steel structure analyzer

Steel structure analyzer KRC-M2 is designed for measuring coercive force of metal products in compliance with IEC 60404-7 and is used for non-destructive testing of chemical-thermal, thermal and thermomechanical treatments, evaluation of mechanical properties and residual stresses. Steel structure analyzer is used for determination of mechanical properties, and for measurement of the hardness of metal products, as well as measurements of products of ferromagnetic alloys in the presence of correlations between the studied parameters.

In addition, the device is used for testing the surface layer of ferromagnetic material for grading the metal in steel grades.

KRC-M2 has an electromagnet transmitter with integrated Hall sensor and removable pole tips.

Operation:

The operation principle of the device consists of following: initially is performed a magnetization of the area of the tested object and, after that, its subsequent progressive demagnetization by the increasing of the field. Next, the intensity of magnetic field is fixed in accordance with the coercive force of material of tested object and the amplitude of signals from the Hall sensor is measured. The main area of using the steel structure analyzer KRC-M2 is analyze the stress-strain state and residual life of pipelines, elevators, cranes and lifts, pressure vessels, steel cables of bridges, and also it used in engineering and metallurgical industries.

Advantages:

• The probe with optional display and buttons control of the main functions.

• Averaging 99 results, with the possibility to use the predictive average.

• Memory: up to 100,000 measurements with the ability to view them on the screen of the device, or transfer to PC.

• Real-time clock – each measurement is saved with the date and time.

• Ability to enter additional scales and additional materials for calibration.

• Calibration mode of basic and additional scales.

• Adjust the brightness of the display, audio, language selection.

• Ability to save backups calibrations on the internal memory of the device.

• Smart sensors with built-in memory of calibrations.

Standard supply:

• Electronic unit

• Probe

• Charger

• Cable for PC connection

• Software for PC

• Case

• Operating manual

Optional accessories:

• Charger

• Cable for PC connection

• Bag

Magnetic test samples

We offer different types of magnetic test samples for MPI, PT and other testings, such as: bars, plates, disks with different types of cracks.

The test blocks are used for:

• quality comparison of different magnetic powders (particle solutions);

• quality assurance of magnetic powders while working with the testing bench;

• for quality analysis during the magnetic particle testing, also to check the correct dosing of magnetic powder in automatic testing.

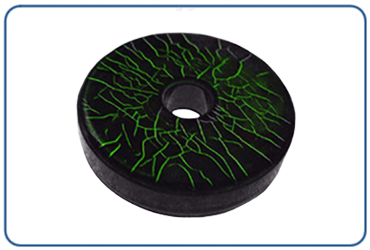

MTU Test Block #3:

The MTU test block #3 (is the reference block type 1 according to EN ISO 9934-2) is used to verify the indication sensitivity of magnetic particle crack detection agents.

The test block is a disk with two types (large and small) of natural cracks (on both sides).

The large cracks are sanding cracks and the small cracks are tension cracks.

The test block has been magnetized by use of the hole in the middle of the test block. The analysis of the test block is made by comparison of the picture with the results of the test block with fluorescent magnetic powder and ultraviolet lamp.